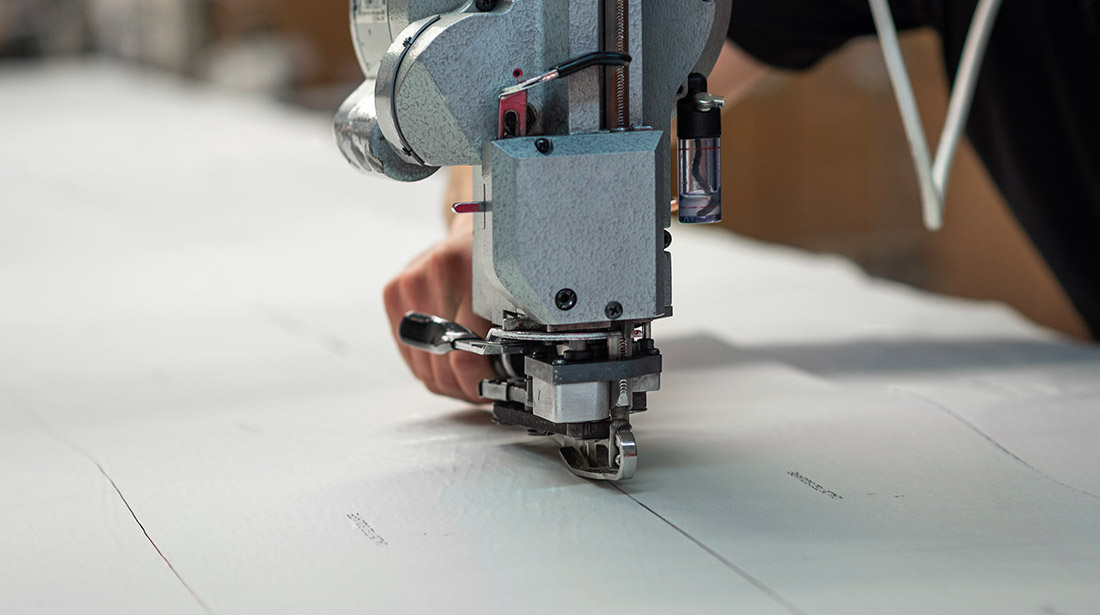

Fiorano d.o.o.

The Fiorano factory was established in 2007, in the province of Vojvodina, in Serbia, between the cities of Sombor and Kula. Since 1980, the area has been recognised internationally as a top-ranking textile centre, so for Fiorano, the challenge was to bring on board the traditional local skills, while at the same time introducing new developments that would allow it to stand out. The factory soon became a centre of excellence for corsetry, as well as for the working conditions offered and in general, for the attention it pays to its employees.

Our people

Employees in Fiorano – 91% of whom are women – have excellent prospects for growth and advancement in the company. In addition to the training opportunities they are offered free of charge, a great deal of importance is placed on team building, with in-house activities frequently organised to develop teamwork. Only three of the employees are from outside Serbia, and this reflects the company’s desire to offer opportunities and valid employment in the local area: Fiorano employs 1,879 people, all of them from the areas around the cities of Sombor and Kula, and offers them a free shuttle service from both cities to reach the factory. In addition to numerous acknowledgements for its support and contribution towards the community, Fiorano has received awards for “Successful Employment of Women” and “Development of Entrepreneurship”.

Respect for the environment

In Fiorano, all the waste water is processed in compliance with the highest environmental standards. In addition, with a view to reducing emissions, by the end of 2021, the plant will be using exclusively electricity from renewable sources. Finally, unnecessary waste will be reduced to a minimum, and unused textiles will be sold so they do not go to waste.

#whomademyclothes

The people who work for us have always been our most valuable resource, and no presentation of our factories would be complete without a word from them. Here are the stories of those who produce our items every day: